高效过滤器泄漏率测试:≤0.01%是否必须?

What is the Acceptance Criteria of HEPA?

什么是高效过滤器的接受标准?

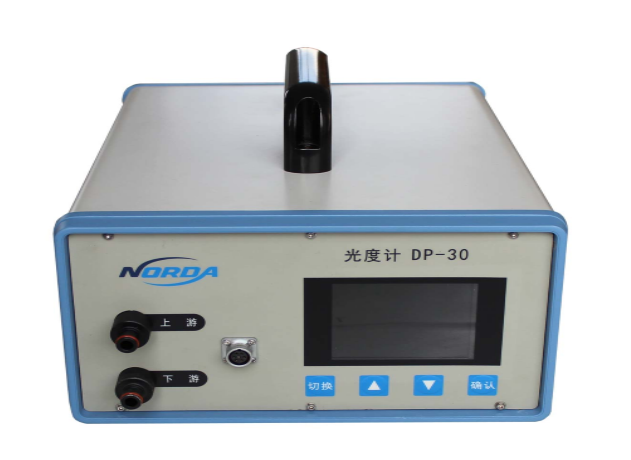

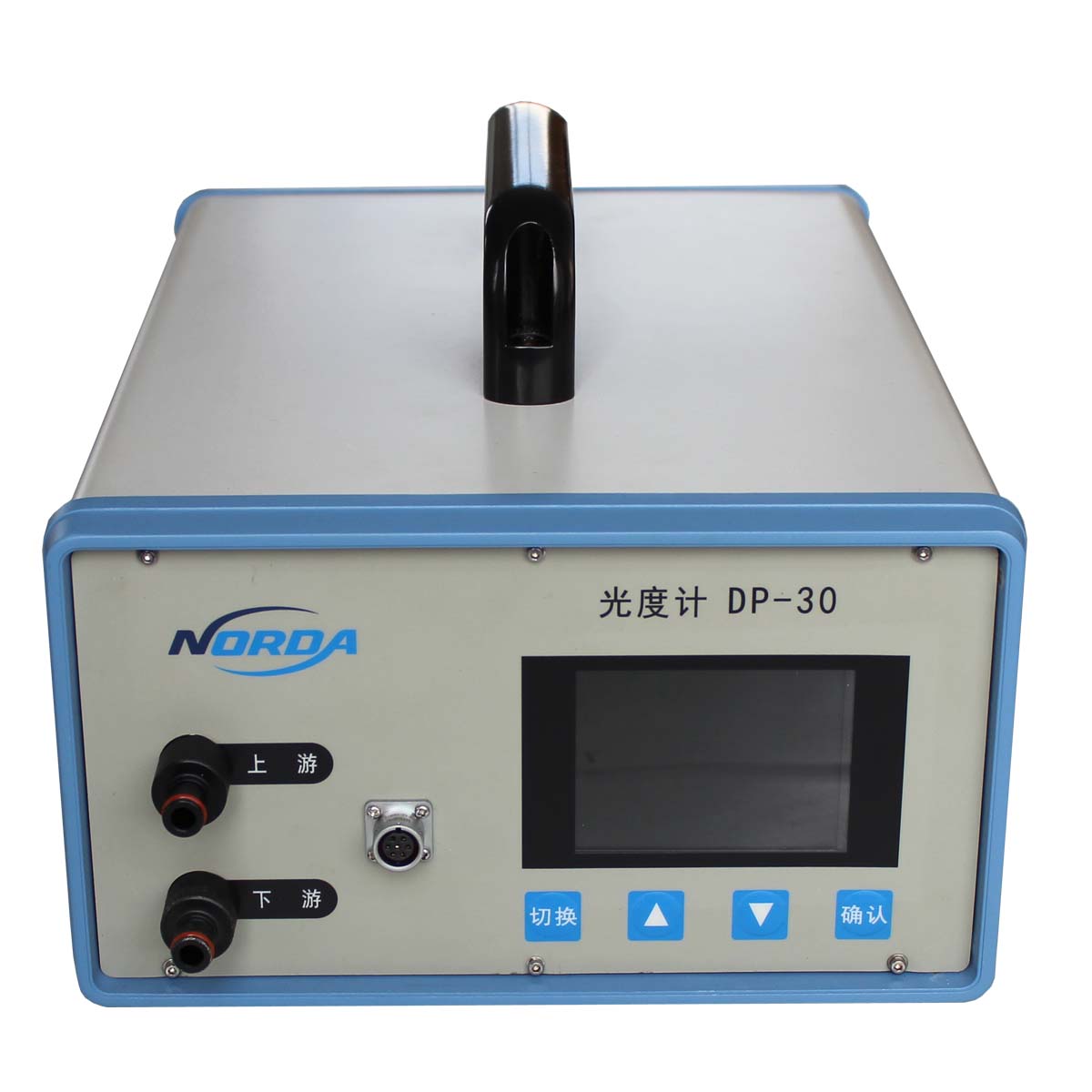

The approach most test standards take regarding acceptance criteria isthat the acceptable leak size limitsare ultimately determined by the customerand supplier. However, a scan test leak size limit of greater than or equal to0.01% has generally been adopted for many applications utilizing HEPA flters orclean areas of varying classifcations. Although the 0.01% leak size has beenused historically and has its origins linked to early generation analog photometertest equipment, establishing a leak size limit of 0.01% as an acceptancecriteria without performing a science and risk-based assessment can result inissues relating to leak testing and can contribute to signifcant operationalcosts if an out of tolerance or failed condition is identifed in a low riskarea. As previouslynoted in Section 6.5, flters are not 100% efcient and areexpected to have some natural or integral penetration of particles near theMPPS. Test acceptance limits become more controversial or problematic whenutilizing lower-rated HEPA flters where the acceptable factory penetration ator near MPPS can be comparable to or larger than the feldtest leak sizeacceptance criteria. This is especially true where the bleed through effectcan occur (see Section 6.9).When purchasing a flter, it is thereforeimportant to consider a flter’s rating as well as how it will be tested after installationin order to avoid unnecessary feld test failures.

大多数测试标准关于高效过滤器泄漏率的接受标准是,可接受的泄漏限度最终由客户和供应商共同确定。但是,对于使用HEPA过滤器或不同级别洁净区的许多应用,大多数采用≤0.01%的扫描测试泄漏标准。尽管0.01%的泄漏率在历史上已经使用过,并且其起源与早期的模拟光度计测试设备相关联,但在没有进行科学和基于风险的评估的情况下,将0.01%的泄漏率标准作为可接受标准将导致与泄漏测试有关的问题,并且如果在低风险区域发现超限或失败情况,将可能会带来巨大的运营成本。过滤器不是100%截留的,并且预计MPPS附近的粒子在过滤器局部或整体可以穿透。当使用较低级别的HEPA过滤器时,工厂进行的MPPS或MPPS附近粒子的可接受泄漏率标准可能等于或大于现场泄漏率测试的接受标准,测试接受标准会变得更具争议和困难。在可能发生泄漏的地方尤其如此。因此,在购买过滤器时,考虑过滤器的等级以及安装后如何进行测试非常重要,以避免不必要的现场测试失败。

ISO 14644-3 [33] gives guidance on how alternative leak acceptancecriteria can be implemented. In a risk-based approach, it may be ideal to haveacceptance criteria that trends with the eficiency of the flters being used orthecleanliness of the room being tested. ISO 14644-3 uses the factory flter efciency rating as the basis of acceptancecriteria negotiation. The leak acceptancecriteria for a photometer leak test and a particle counter based leaktestshould be the same, as the theory and methodology behind leak sizing isidentical for both methods. If performedproperly, a leak test with a photometerand a particle counter will result in the same leak size (Meek, et al., 2011[121]).

ISO 14644-3 [33]提供了有关如何实施泄漏替代标准的指南。 在基于风险的方法中,理想的接受标准是,该接受标准可以反映所使用过滤器的效率或所测试房间的洁净度。 ISO 14644-3使用工厂过滤效率等级作为接受标准协商的基础。光度计泄漏测试和基于粒子计数器的泄漏测试的泄漏接受标准应该相同,因为两种方法背后的理论和方法是相同的。如果执行得当,使用光度计和粒子计数器进行的泄漏测试将得到相同的泄漏率结果(Meek等,2011 [121])。

A leak detected in excess of 0,01 % of the upstream massconcentration is deemed to exceed themaximum allowable penetration. However,for filter systems of an integral efficiency at MPPS ≥ 99,95 %and less than99,995 %, the acceptance criterion is 0,1 %.

如果检测到的泄漏量超过上游浓度的0.01%,一般认为该泄漏率超过最大允许标准。但是,对于整体效率MPPS≥99.95%且小于99,995%的过滤器系统(如H13过滤器),接受标准为0.1%。

If filter systems of an integral efficiency lower than 99,95 %at MPPS are to be tested, a different acceptance criterion are necessary, basedon agreement between customer and supplier.

如果要测试 MPPS 整体效率低于 99.95% 的过滤系统,则根据客户和供应商之间的协议,需要不一样的接受标准。

The flters for depyrogenation tunnel

用于去热原隧道的高效过滤器

The flters ftted to a depyrogenation tunnel are subject toprolonged periods of high temperature operation, so standard flters are notsuitable. Special flters rated to 350°C are available with a manufacturerguaranteed efciency of 99.99% for 0.3 µm particles (note that the FDA defnitionof a HEPA is > 99.97% at 0.3 µm) at a temperature of 350°C) with a ceramicmaterial used for the media to frame seal. Recently there have been advances inthe materials available and flexible sealants are being introduced that canreduce the heat up time and reduce the risk of sealant cracking. Traditionalflters need to have a controlled heat up and cool down time (typically not toexceed 1°C per minute; the rate should be confrmed with the flter supplier) toprevent heat stress damage to the seals. Often the systems are maintained hotduring periods of non-use to reduce the heat cycling on the flter.

安装到去热原隧道中的过滤器需要经受长时间的高温操作,因此不适用标准过滤器。厂家使用陶瓷材料用于滤材与边框的密封可提供耐受350℃的对0.3 µm颗粒的效率为99.99%的特殊过滤器(注,FDA对HEPA的定义为> 99.97%@0.3 µm)。最近,可用的材料有了进步,并且引入了柔性密封剂,可以减少加热时间并降低密封剂开裂的风险。传统的过滤器需要具有受控的加热和冷却速度(通常不超过1℃/分钟;应与过滤器供应商确认该速率),以防止热应力损坏密封件。通常,在不使用期间,系统会保持高温,以减少过滤器的加热循环。

Filters used for depyrogenation tunnel are generally H14. Theseflters can be full face scan leak tested on installation, but after the initialheating cycle (burning in the flter, which usually results in the flter gradebecoming equivalent to H13) traditional testing is not recommended. The oilaerosol (if it is Polyalphaolefn (PAO)) will load onto the flter and burn off,giving offunhealthy fumes, and may load the flter media; this is usually more fragileafter burn in as the binder holding the media together has off-gassed.DEHS (Diethylhexyl Sebacate) is an alternative oil that may evaporatefaster.

用于去热原隧道的过滤器通常是H14。这些过滤器可以在安装时进行全面扫描泄漏测试,但是在首次加热循环之后(过滤器会燃烧,通常会导致该过滤器等级与H13相当),不建议再进行传统测试。因为气溶胶油(如聚α烯烃(PAO))将被截留到过滤器上并燃烧,从而产生不健康的烟雾,并可能堵塞过滤介质。由于将过滤器介质粘合在一起的粘合剂在燃烧会放气,通常导致过滤器变脆。DEHS(癸二酸二乙基己酯)是一种可能会更快蒸发的替代油。